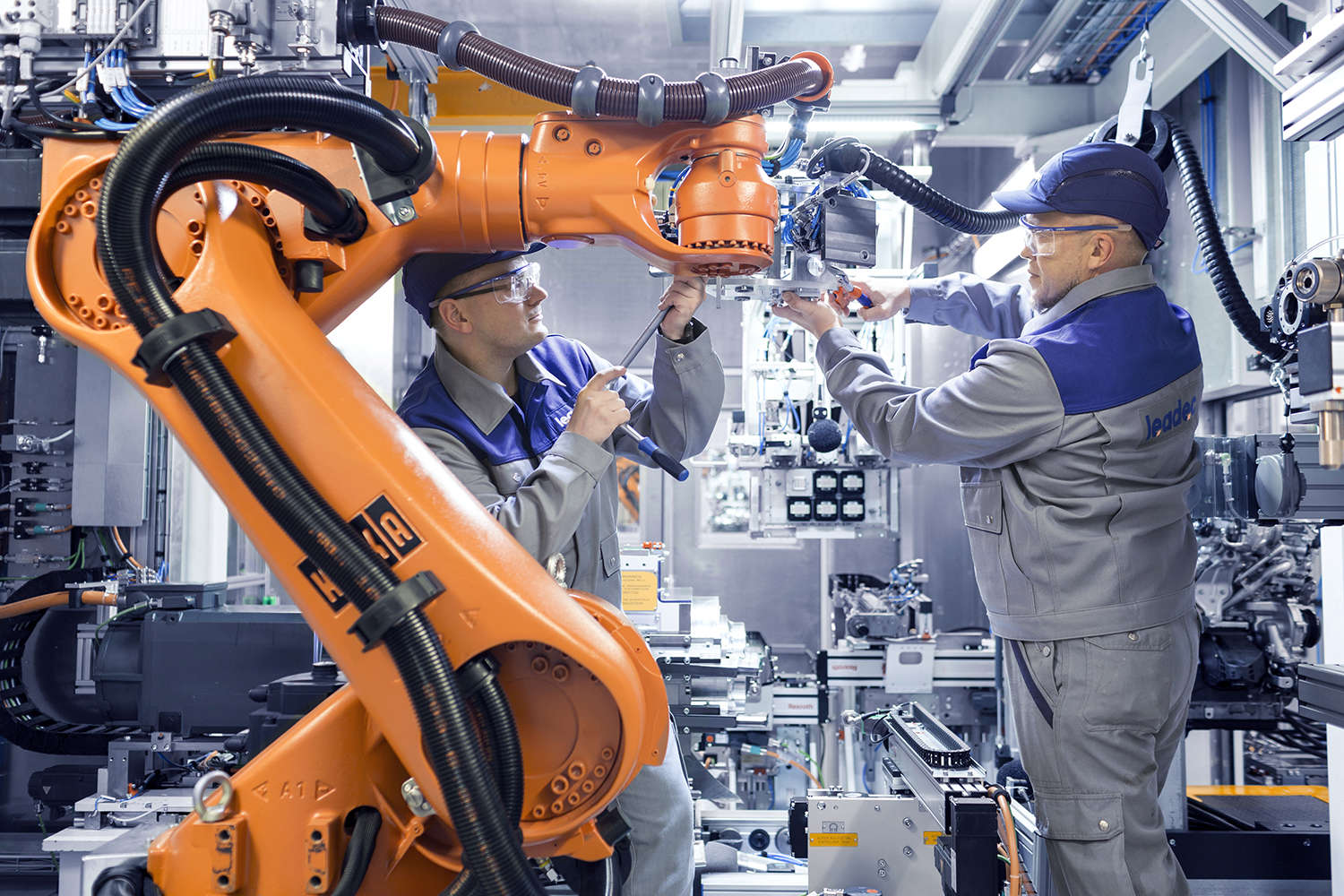

Production Equipment Maintenance

Our comprehensive maintenance services keep your production equipment running at peak performance. With regular maintenance and overhauls, we can extend the life of your machinery. This reduces the risk of defective finished products and the need for rework, resulting in less waste and lower costs. Properly maintained equipment also increases workplace safety and reduces the incidence of workplace accidents.